ART-NANO CHROME

We provide a wide range of Services

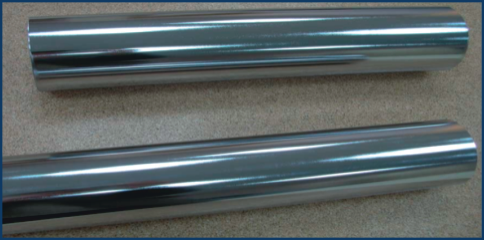

The ART-NANO Chrome additive combines exceptional thermal and chemical stability with nano-scale precision, enhancing the performance and durability of hard chrome coatings. By integrating our carbon nanomaterials into plating electrolytes, we help achieve smoother, harder, and more corrosion-resistant surfaces—ideal for demanding industrial applications.

- The ART-NANO Chrome additive’s high thermal and chemical stability;

- Chromium-plating speed range from 0.7 up to 1.42 mcm / min. Chromium-plating 50-55% reduction in time in comparison with the multipurpose electrolyte;

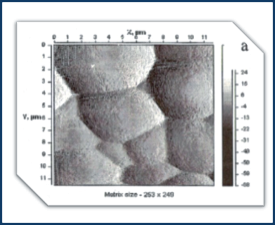

- The electrolyte high scattering power and the metal division according to macro-and micro-profile;

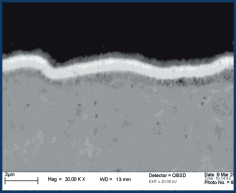

- Providing the necessary micro-cracking, low crystallinity;

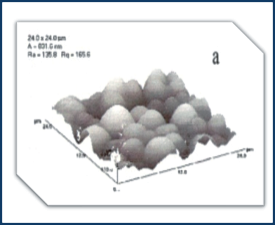

- Microhardness variation range from 800 to 1270 HV 0.1;

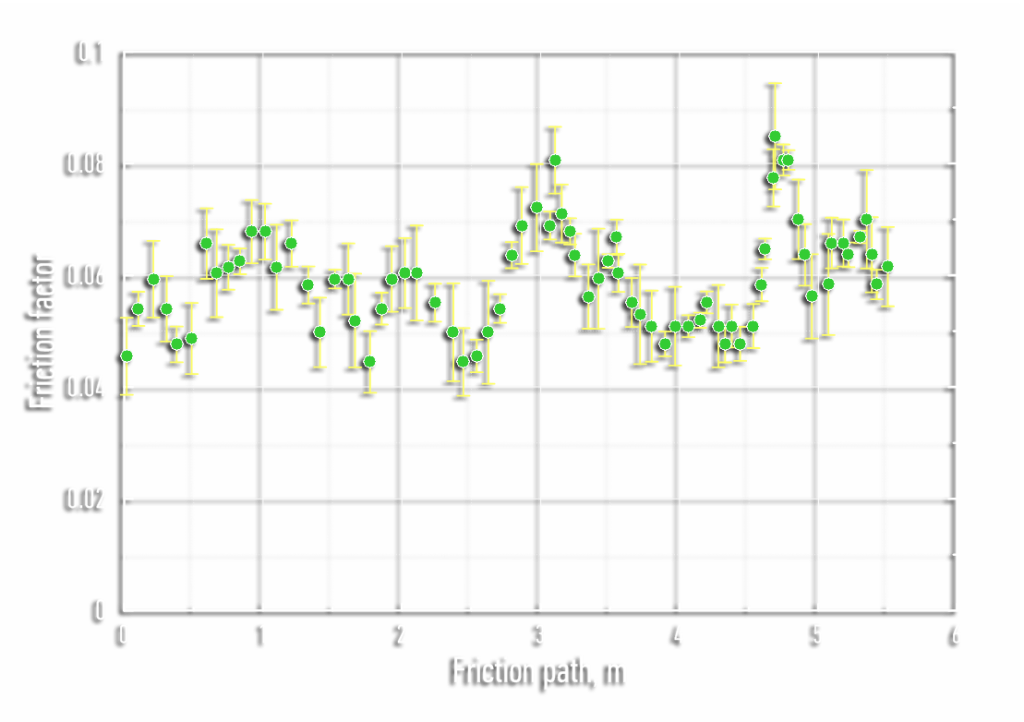

- The ART-NANO Chrome — St40 chromium coating dry friction coefficient is 0.05-0.07, high resistance to corrosion abrasion obtained;

- Reduce in electricity consumption by 40-50% in comparison with the multipurpose chromium- plating electrolyte;

- High potential for subsequent polishing;

- Increased thermal stability.

The complete absence of porosity

Black Nano Chrome

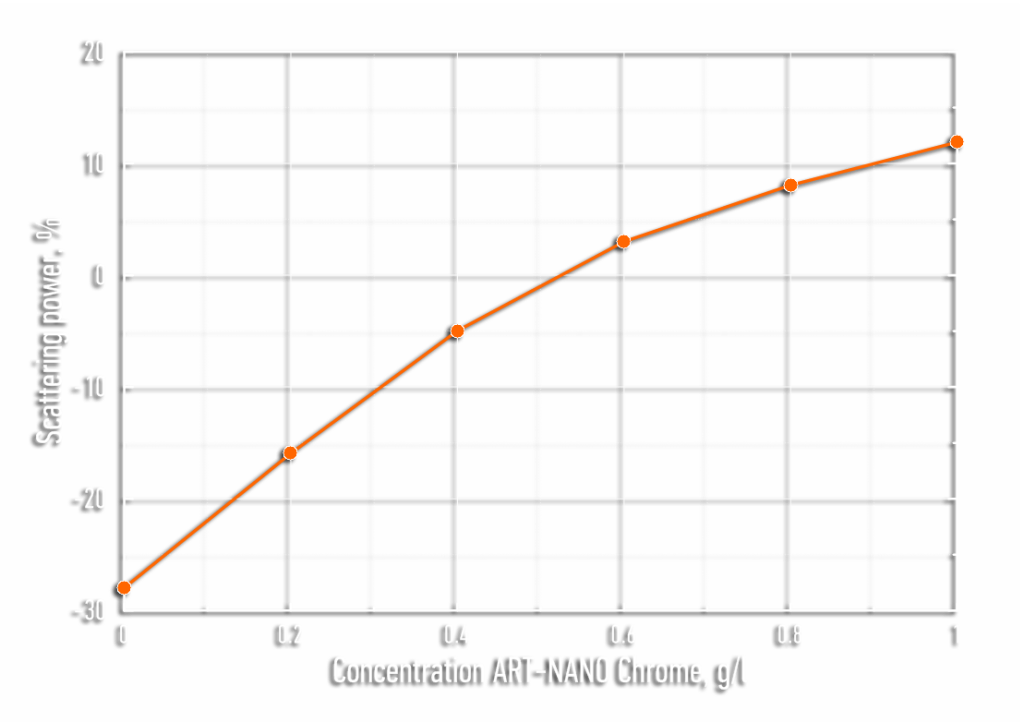

Changing the scattering power of the electrolyte as a function of ARTome chromium concentration (ik = 50 A/dm2, T = 55° C)

Changing the friction coefficient for ARTome Indenter ST

| THE COATING CHARACTERICTICS | STADY-STATE CURRENT REGIME | TRANSIENT CURRENT REGIME |

| ART-NANO Chrome low-concentration electrolyte | ART-NANO Chrome low-concentration electrolyte | |

| Microhardness, HVO.1 | 1050 — 1240 | 1150 — 1300 |

| Porosity, pores/cm2 | No more than 0.1 | No porosity |

| 5% salt spray chamber trials at T=35° C | 122 h — no visible changes of surface 152 h — pitting corrosion primary centers | More than 160 h — no visible changes of surface |

| Dry friction coefficient Intender ST-40 | 0.05 — 0.07 | 0.05 — 0.07 |

Corrosion tests were carried out according to GOST 9.30885 with the mandatory inspection of parts after each test cycle (24 h) Microhardness measurements. Digital Hardness Tester DURAMIN 5 (Denmark)

The intender load 100 g

(polished stok)

The intender load 200 g

(polished stok)

The intender load 100 g

The intender load 200 g

Have Questions?

Discover how ART-NANO Chrome can improve your hard chrome plating process—delivering coatings with superior hardness, wear resistance, and corrosion protection, thanks to the exceptional thermal and chemical stability of our nanomaterial additive. We’re ready to help you optimize your surface finishing solutions.

Our Customers

Our projects have been successfully implemented in the following countries:

— United Arab Emirates

— South Korea

— France

— Bulgaria

"About ART-NANO CHROME"

Would you like to start a project with us?

We’re ready to bring our expertise in nanomaterials to your challenge.

Whether it’s R&D, custom formulation, or industrial-scale implementation — let’s build the future together.