ART-NANO CHEMICAL

We provide a wide range of Services

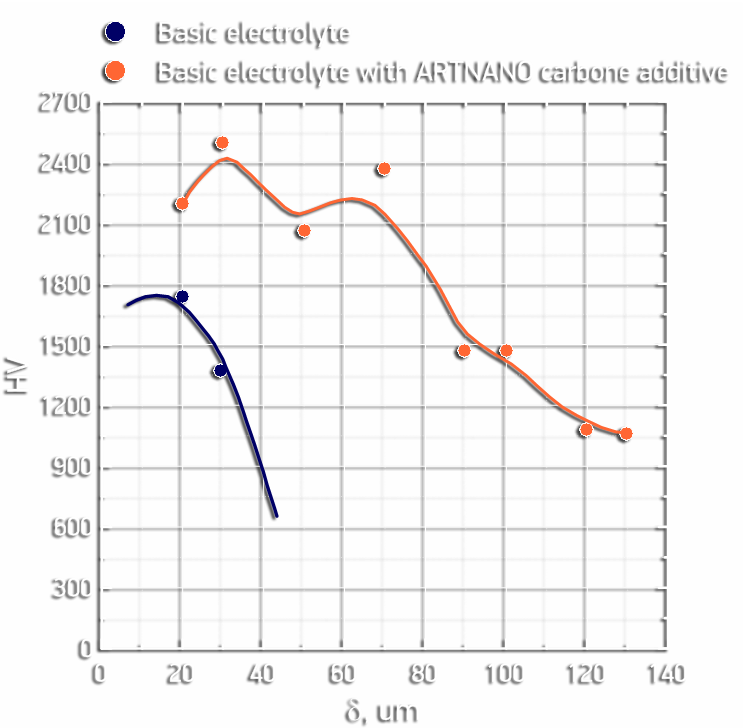

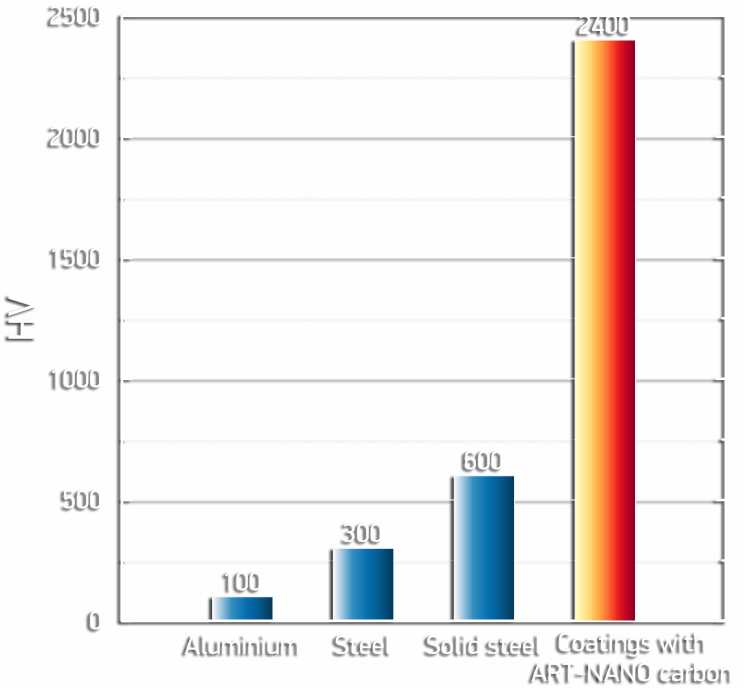

Anodic treatment is the most promising method in comparison with existing techniques of coatings application to aluminum, magnesium, titanium alloys. This method allows to obtain coatings with good mechanical, dielectric, heat resistance, protective and decorative properties. The endurance of the coatings applied to aluminum and magnesium alloys exceed s that of all the existing materials in the modern technological process.

VALVE METALS ANODIC TREATMENT AT TRANSIENT

CURRENT LOADS IN ELECTROLYTES CONTAINING

NANOSIZED CARBON ADDITIVES.

MAIN APPLICATION AREAS

- Petroleum and coal industry — the creation of corrosion and wear-resistant coatings for drilling, coal and oil production, oil refining equipment.

- Rocket engineering — developing heat-,erosion- and wear-resistant coatings for rocket engines.

- Mechanical engineering — friction couples, slide bearings, gears, forcers, cylinders, internal combustion engines’ face seals, tools and machines for different purposes in shipbuilding, aircraft industry, agricultural machinery details.

- Metallurgical engineering — permanent casting equipment, molted casting bars, furnace lining, heat shields, etc.

- Construction industry — Aluminium profiles, assembly design, and other constructions’ processing. Windows production. Protective and decorative coatings.

- Light industry — thread guides, shuttles and other parts of the textile and sewing machinery.

- Medicine — Surgical implants.

Technological processes developed with ART-NANO application allows

To develop multifunctional composite anodic-oxide coatings with unique physical, mechanical and operational properties:

- Microhardness up to 2400 HV;

- Coating adhesion to the substrate at the level of 350-370 MPa ;

- The coating boundary friction coefficient in pair with steel 0.02-0.03;

- The coating dry friction coefficient in pair with galvanic chromium less than 0.05. Wear rate 10-11-10-10 mg/m;

- A breakdown voltage of up to 5 kV.

ART-NANO carbon additive introduction into the electrolyte also allows:

- To structure the surface.

- Increase the rate of coatings formation in 1.5-2 times.

- Reduce energy consumption in 1.7-2.5 times due to the working current density and voltage reduction.

- Achieve nanoscale coatings and coating thicker than 300 microns in all types of aluminum alloys, including high-silicon casting alloys.

- To develop coatings for outer and inner surfaces of friction units of different shapes.

- Maintain the original dimensions of parts after coating application.

- Use environmentally friendly electrolytes.

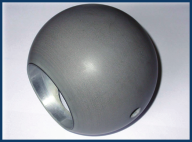

Shut-off gas fitting ball

Shut-off gas fitting ball

Press molds and the internal combustion engine details

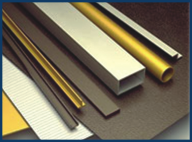

Aluminum profiles protective and decorative treatment

Aluminum profiles protective and decorative treatment

Have Questions?

Explore how anodic treatment of valve metals under transient current loads—enhanced with nanosized carbon additives—delivers superior oxide layers with improved hardness, corrosion resistance, and functional properties. This advanced approach outperforms conventional methods and opens new possibilities for high-performance surface engineering. We’re ready to share insights and support your application.

Our Customers

Our projects have been successfully implemented in the following countries:

— United Arab Emirates

— South Korea

— France

— Bulgaria

"About Anodic Treatment with ART-NANO"

Would you like to start a project with us?

We’re ready to bring our expertise in nanomaterials to your challenge.

Whether it’s R&D, custom formulation, or industrial-scale implementation — let’s build the future together.