ART-NANO CHROME

- The ART-NANO Chrome additive's high thermal and chemical stability;

- Chromium-plating speed range from 0.7 up to 1.42 mcm / min. Chromium-plating 50-55% reduction in time in comparison with the multipurpose electrolyte;

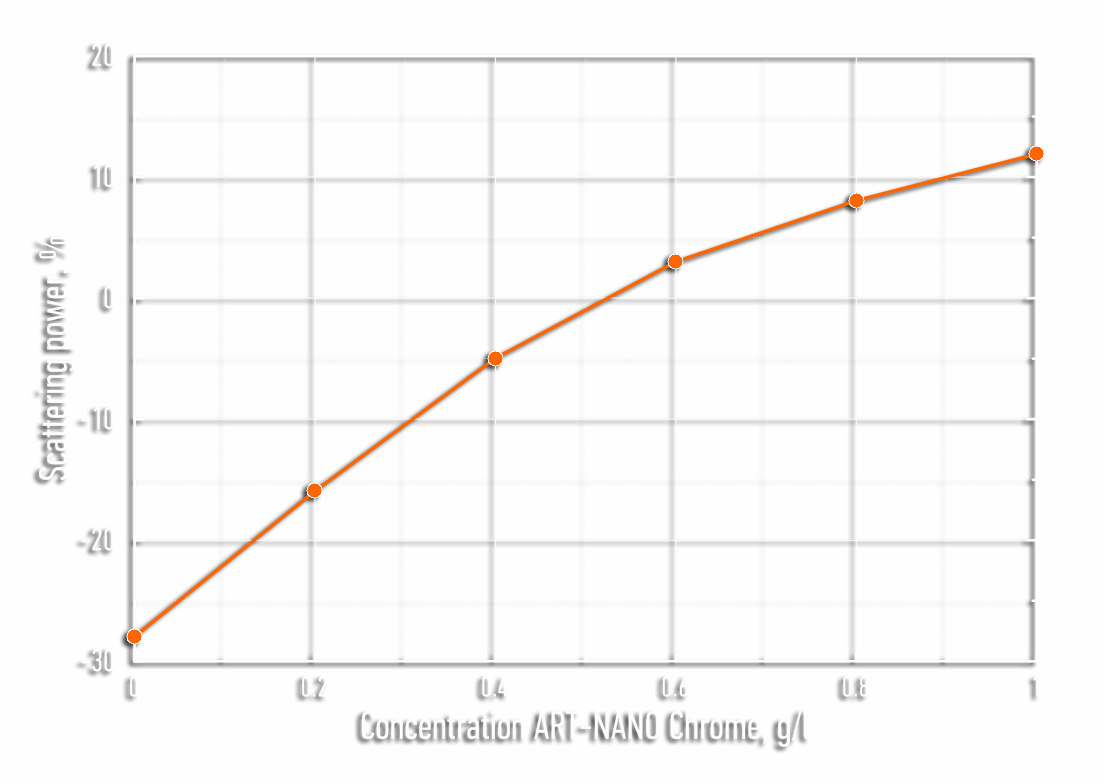

- The electrolyte high scattering power and the metal division according to macro-and micro-profile;

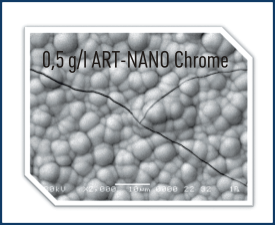

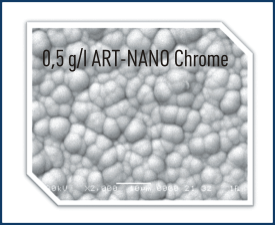

- Providing the necessary micro-cracking, low crystallinity;

- Microhardness variation range from 800 to 1270 HV 0.1;

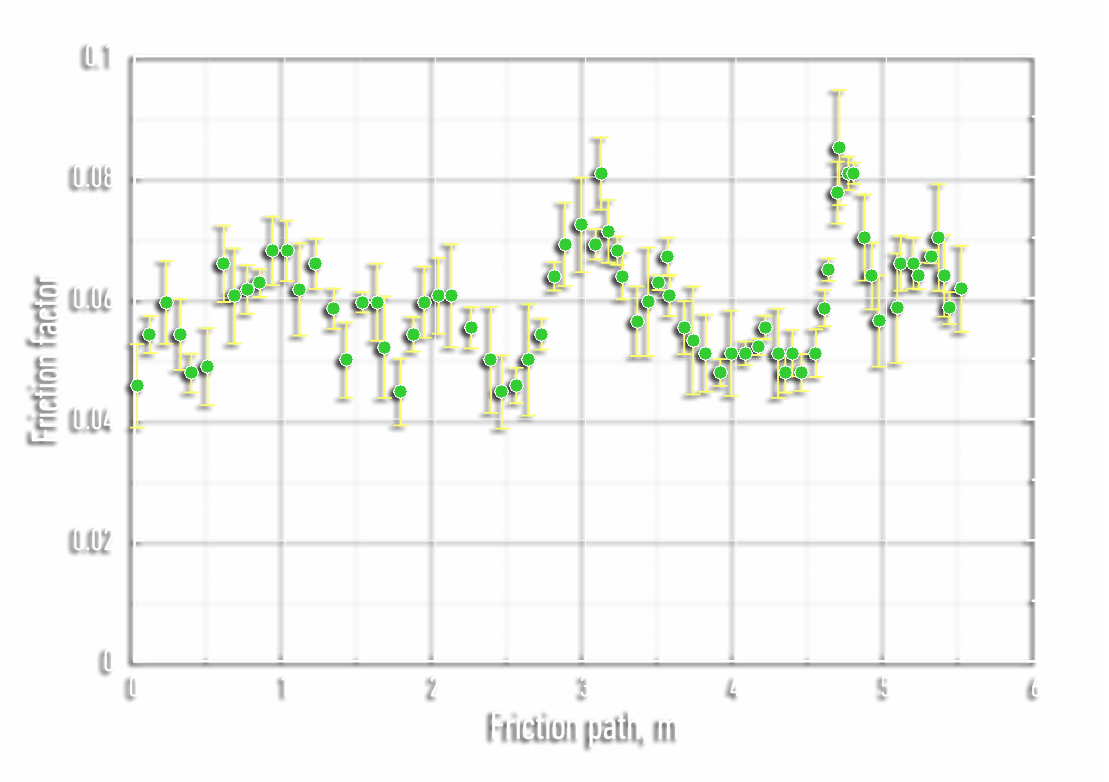

- The ART-NANO Chrome - St40 chromium coating dry friction coefficient is 0.05-0.07, high resistance to corrosion abrasion obtained;

- Reduce in electricity consumption by 40-50% in comparison with the multipurpose chromium- plating electrolyte;

- High potential for subsequent polishing;

- Increased thermal stability.

|

|

|

|

|

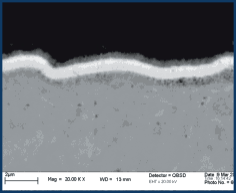

| The complete absence of porosity | Black Nano Chrome |

|

|

|

|

|

|

| Changing the scattering power of the electrolyte as a function of ARTome chromium concentration (ik = 50 A/dm2, T = 55° C) | Changing the friction coefficient for ARTome Indenter ST |

| THE COATING CHARACTERICTICS | STADY-STATE CURRENT REGIME | TRANSIENT CURRENT REGIME |

| ART-NANO Chrome low-concentration electrolyte |

ART-NANO Chrome low-concentration electrolyte |

|

| Microhardness, HVO.1 | 1050 - 1240 | 1150 - 1300 |

| Porosity, pores/cm2 | No more than 0.1 | No porosity |

| 5% salt spray chamber trials at T=35° C |

122 h - no visible changes of surface 152 h - pitting corrosion primary centers |

More than 160 h - no visible changes of surface |

| Dry friction coefficient Intender ST-40 |

0.05 - 0.07 | 0.05 - 0.07 |

Corrosion tests were carried out according to GOST 9.30885 with the mandatory inspection of parts after each test cycle (24 h) Microhardness measurements. Digital Hardness Tester DURAMIN 5 (Denmark) |

|||

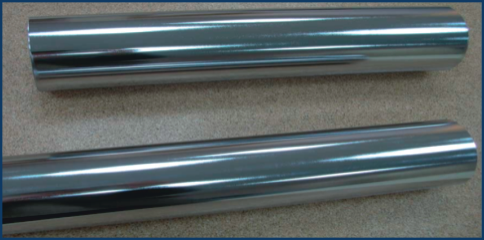

Steadystate current regime (polished stok) |

Transient current regime (mat stok) |

||

|

|

|

|

| The intender load 100 g | The intender load 200 g | The intender load 100 g | The intender load 200 g |